faster lead times, higher margins, proven results.

Forget endless meetings and pretty presentations. What you need is a system that works – one that eliminates firefighting, improves flow, and powers real business growth.

Apply our proven, design-driven methodology to eliminate firefighting, improve flow, and drive measurable results so you can focus on growth.

Build self-sustaining operations designed to run without constant management oversight.

Cut lead times by up to 80% while delivering millions in annual savings

Here are some areas where we’ve helped companies overcome their challenges and achieve Operational Excellence.

Keep in mind, it’s not the whole list.

Ensure every process works from end-to-end thereby improving flow, eliminating bottlenecks,

and sustaining growth.

Create structured, organized workspaces that improve productivity and support long-term process discipline.

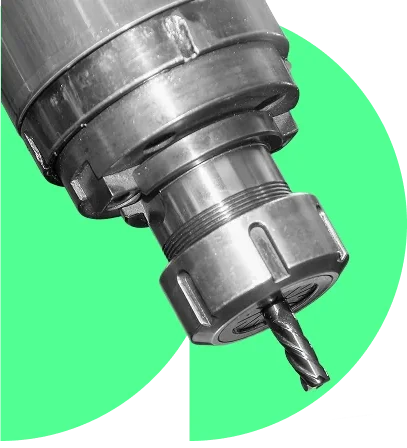

Design workflows and layouts that streamline the build of complex machines, reducing downtime

and increasing throughput.

Apply the right lean principles to optimize your

MRO processes end-to-end.

Go beyond theory with hands-on, technical lean consulting that eliminates inefficiencies at the source and creates sustainable, self-healing operations.

Design process flows and layouts tailored to the challenges of large, stationary builds to improve visibility and coordination across teams.

Engineer facility layouts that support flow from

end-to-end for maximum productivity.

Achieved 30% faster turnaround times in MRO operations.

Define and implement a transformation plan with measurable outcomes.

Custom, math‐based value‐stream design, not generic frameworks.

Hands‐on execution with your team; capability stays with you.

Proven future‐state design; client‐owned and sustainable.

Solve for end‐to‐end flow, not one‐off events.

Visible, self-healing flow across the

value stream.

Repeat what you already know, without offering a fix.

Apply frameworks based on trends,

not your actual operations.

Prioritize discussion over

disciplined design.

Fix easy things while leaving root

causes untouched.

Improve one step while breaking the

rest of the system.

Focus on progress in silos, not performance across the whole value stream.

Define and implement a transformation plan with measurable outcomes.

Custom, math‐based value‐stream design, not generic frameworks.

Hands‐on execution with your team; capability stays with you.

Repeat what you already know, without offering a fix

Apply frameworks based on trends, not your actual operations

Prioritize discussion over disciplined design.

Proven future‐state design; client‐owned and sustainable.

Solve for end‐to‐end flow, not one‐off events.

Visible, self-healing flow across the value stream.

Fix easy things while leaving root causes untouched

Improve one step while breaking the rest of the system

Focus on progress in silos, not performance across the whole value stream

We skip the endless assessments and get started with a hands-on design workshop. From day one, the your team is learning, making decisions, and actively starting their transformation — with real progress, not just a plan.

We focus on designing the value stream from day one because that’s where real improvements begin. Along the way, we use the right lean tools to support it.

Not just talk. We work alongside your team to ensure their long-term success.

We educate your team so they can operate the system without the need for endless consulting and without needing managerial intervention.

We don’t lock you into contracts. If we’re not delivering value, you shouldn’t have to keep us around.

Our knowledge is what separates us from the rest. Duggan Associates pioneered Operational Excellence almost 15 years ago. Our books and resources are a detailed guide for our design process to transform your operations. We don’t just brainstorm and run Kaizen events. Instead, we teach and guide our clients through our design methodology. Everything we do is teachable and repeatable. We teach our clients to succeed after we leave.

“It’s really focused on customers, markets, and strategy. Operations get time – it’s not ignored. The difference is we don’t have to talk about it all the time.”

“I’ve worked with Kevin Duggan over the last 15 years, first at United Technologies and now at FMC Technologies. He’s highly competent in lean and Operational Excellence, articulate, and engaging. With his expertise and presentation style, I strongly recommend him for corporate training and keynotes.”

“Duggan Associates helped us improve productivity, efficiency, and our culture of continuous improvement with tools like Value Stream Mapping, 5S, and visual flow. Their focus on high participation and sustainable transformation delivered quick wins and built lasting capability. Their proactive support was invaluable.”

“Tim spent three days with us teaching Operational Excellence office methods and guiding us to apply them to one of our core value streams. By the third day, the team was fully sold and motivated to act immediately. This is a credit to the OpEx methods, and especially to Tim’s no-nonsense teaching, his ability to answer tough questions, and his guidance in creating our future state design and action plan.”