Situation

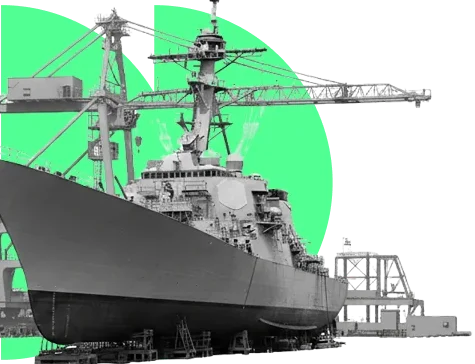

A large, vertically integrated naval shipbuilder needed to become a “preferred supplier” to its government customer-meeting delivery dates, hitting target costs, and launching ships on schedule without firefighting. The environment combined construction and complex fabrication with extremely high mix and customization.

Challenge

- No industry playbook for applying OpEx to a construction build at this scale.

- Fabrication shops were a PhD-level problem in mixed-model and shared-resource flow.

- 5,000+ people needed a way to “see” flow and act before it broke down.

What We Did

Designed a company wide Operating System: a blueprint for how material and information move from raw material to complete ship, with clear normal and abnormal flows, and standard

responses, removing the reliance on management intervention.

Scoped three critical areas:

- Pre-Outfit (PO): Station design, pre-flight, and execution standards that let teams hit designed build times “each and every time.”

- Fabrication: Defined product families and Guaranteed Turnaround Times (GTTs) for each value stream; capability analysis and leveling so PO always receives what it needs.

- Warehouse: Dock-to-stock and stock-to-ship GTTs together with an early-warning system (visual FIFO lanes, color-coded family signals, standard work for kitting and shipping).

Education first: Trained leaders and the workforce in the OpEx process (design flow, make flow visual, standard work for flow and abnormal flow) to create a common language and

self-correction at the source. Without embedded standard work, progress will inevitably slide.

Implementation Highlights

- PO < > Fab < > Warehouse linkage: Daily signal cadences (3x daily) connect areas in a closed-loop customer delivery system.

- Early-warning boards: Parts checklists and flow-disruption tracking by unit/station enable fast containment without meetings.

- No scheduling needed: Visual family signals tell the warehouse what to pick and ship next; supervisors don’t need to direct sequencing.

Results

- Predictable execution: Product families in Fab “always achieve GTTs,” stabilizing the upstream supply to PO.

- Shorter, reliable material cycles: Defined GTTs for dock-to-stock and stock-to-ship with FIFO flow reduced handoffs and delays and provided immediate visibility when flow slipped.

- Management load removed: Visual controls and standard responses eliminated many daily/oversight meetings while keeping flow on time. Freeing time to focus on growth.

- Enterprise alignment: A single operating system across PO, Fabrication, and Warehouse tied execution to ship launch dates and cost goals-key to Preferred Supplier status.

Why It Worked

- Blueprint before tools: Designed normal and abnormal flow and responses first; then taught everyone how to see and fix flow.

- Guaranteed Turnaround Times: GTTs replaced scheduling guesses with commitments the floor could meet and verify visually.