Challenge

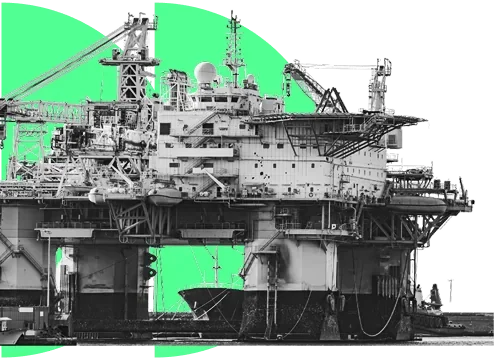

A leading industrial manufacturer, supplying the Energy and Oil & Gas markets, faced stalled growth despite years of efficiency projects. Tools like 5S, SMED, and TPM improved productivity but did not create a path to expansion. Operations were stuck maintaining the status quo, while leadership sought a way to link operational gains directly to sales and innovation.

What We Did

Duggan Associates worked with site leadership to implement Value Stream Design across manufacturing, warehouse, office, and supplier networks. Flow was made visible to every operator, with clear normal/abnormal signals and standard responses. Beyond the factory, flow was extended into quoting, logistics, and even supplier networks, creating a truly end-to-end operating system.

Implementation Highlights

- Shop Floor Flow: Product families and FIFO lanes made status visible, eliminating firefighting and enabling guaranteed turnaround times.

- Office Flow: A redesigned quoting process with daily workflow cycles cut interruptions, reduced quote lead times, and increased throughput.

- Warehouse & Supply Chain: Visual FIFO lanes and supplier-linked andon systems provided real-time early warnings – shrinking response time from days to hours.

Results

- +30% more quotes per day with fewer staff while reducing processing time by 75%.

- 23% higher value capture on quoted items after flow redesign.

- Lead time and inventory reductions allowed the plant to move from holding finished goods to “make and ship” reliability.

- Faster innovation cycles – three complex products launched in one year versus 10 years for competitors.

Why It Worked

By linking Value Stream Design to growth, not just efficiency, the transformation freed up resources that were redeployed into sales, customer support, and innovation. Operations shifted from being a drag on growth to powering it – enabling the business to double in size, expand product mix, and capture significant market share.